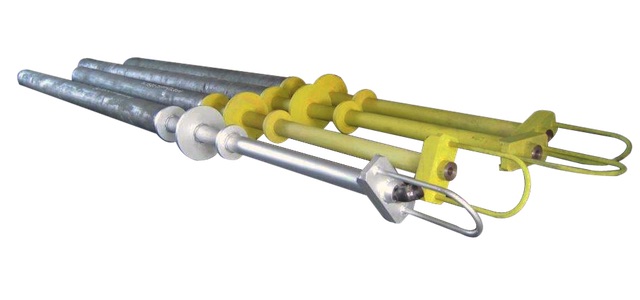

Refractory Injection Lance, offered by us is widely used in varied steel industries for strength and performance. Composite constructions is available in thermally stable and slag resistant vibrocast refractory materials having high density, strength and structural integrity with divergent outlets.

Refractory / Monolithic Injection Lance

We CUSTOMISE REFRACTORY INJECTION LANCE DESIGN keeping in mind the requirements of various clients.

The TOP REFRACTORY MONOLITHIC LANCE technology integrates a variety of functions which expands the metallurgical and operational capabilities.

FOLLOWING MEDIA CAN BE BLOWN:

Gaseous Fuels (Nitrogen, Argon, Oxygen etc.) for :

Metallurgical Power (Lime, Alumina, Synthetic Slag, Iron oxide) for:

All international shapes and tailor made.

Kandi Engineering was incorporated in 1982, and started initial trading activities at Manor (Maharashtra), an Industrial Area just 85 kms from Mumbai, INDIA. Cost saving and good quality being the motto of the management, the production started in 1995 for manufacture of industrial products related to Steel & Metallurgical Industry.

Read More