The Thermal Cutting Torch uses a preheat flame to elevate the temperature of the material to be cut to 1500 to 1900 oF. When the steel become cherry red a high pressure jet of oxygen is directed the pre-heated metal. The result is the metal is rapidly oxidized or it burns. This process works on material that will oxidize. If it will not rust, it cannot be cut readily cut with a Thermal system.

Cutting steel with an exothermic torch requires no preheat or cleaning.

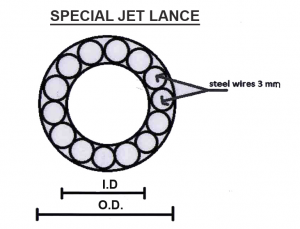

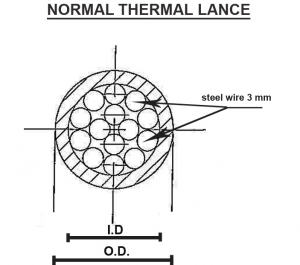

Exothermic process also utilizes oxidation. However, the exothermic process uses alloys in the material in the Burning / Thermal Lance as the fuel and produces temperatures of 7200 oF. Burning / Thermal Lance consists of an outer tube filled with special alloy wire. The exothermic reaction (Oxidation) occurs when the tip of the rod is heated to its kindling temperature (2800 oF) and pure oxygen is introduced through the lance. The chemical reaction will continue until the lance is consumed or the oxygen flow is turned off. The only gas required for this cutting operation is pure oxygen.

The exothermic process relies on OXYGEN VOLUME and PRESSURE. Without proper volume of oxygen the cutting process will not work and creates hazards to the operator. Minimum and maximum volumes and pressures are listed with each size burning lance. You MUST supply the minimum volume and pressure for safe efficient operation. For all of the large burning lance you CAN NOT operate them with a single liquid oxygen tank.

| Size of Pipe | O.D | I.D | Size of Wire |

|---|---|---|---|

| 10 N.B. | 17 mm | 11 mm | 3 mm |

| 15 N.B. | 21.5 mm | 15 mm | 3 mm |

| 20 N.B. | 27.5 mm | 21 mm | 3 mm |

| Standard Length | 3 mtr, 4.5 mtr, 5.5 mtr or as per Customer Requirement |

| Tolerances | 0.5 mm +/- |

| End Finish | Plain end, Threaded and Coupled |

| Packing | As per Customer Requirement |

| Size of Pipe | O.D. | I.D. | Size of Wire |

|---|---|---|---|

| 8 N.B. | 13 mm | 9 mm | 3 mm |

| 10 N.B. | 17 mm | 13 mm | 3 mm |

| 15 N.B. | 21.5 mm | 17 mm | 3 mm |

| 20 N.B. | 27.5 mm | 23 mm | 3 mm |

Burning Lance Required Equipment

Burning / Thermal Lance Application

Burning / Thermal Lance Application

Burning Lance is the product developed for the purpose of increasing the heat quality generated from the lance, by improving the cutting efficiency with the cutting core wires of several pieces built in the combustion steel pipe.

The lance will cut most ferrous and non-ferrous metals as well as concrete and refractory. Benefits over conventional cutting methods include cutting speed and the ability to cut thick rusty metals.

The standard diameters and lengths are 12.7 mm O.D., 13.5mm O.D., 17mm O.D., 21.7 mm and 27.2 mm O.D.

Length – 2750mm, 3000mm or as per customer’s requirement.

Yes, we can meet the customer’s requirement in length and diameters to meet their specifications, provided the minimum quantity of requirements is met.

The end finish is the Plain End, Threaded and Coupled.

The difficult to cut materials in gas cutting and mechanical cutting i.e. not only limited to iron and steel, the stainless steel, alloys such as brass, non-ferrous metals , ceramic, etc. can be simply and quickly cut off and bored without noise and vibration at the high temperature of 3600 oC. It is optimum for cutting and boring special steel, cast steel, pig iron, slag and concrete. Heat source is not required for the equipment.

Oxygen Cutting rods, Lance holder set, sufficient oxygen supply (35 cubic / min, each rod burns for four and half minutes – approx. 160 total cubic feet). Oxygen hose: 25’ – 50’ of 3/8” or ½” (smaller than 3/8” hose will reduce the flow of oxygen beyond effective operation). Oxygen high volume regulator (head pressure 200 PSI required). Ignition equipment require for Oxy-Acetylene Torch and Flame resistant protective clothing.

To start the operation, the end of the lance is heated to ignition temperature by means of an Oxy / Acetylene torch. Oxygen is then fed through the lance promoting fusion at the lance point, and the reaction becomes self supporting.

The boring operation is not difficult, the lance should be fed into the hole as boring progresses. Holes 3 meters in length can be bored horizontally, although it would be better to incline the object, if possible, to allow the slag to flow freely out.

Boring vertically down can be carried out successfully, but after the first 12″ the Oxygen pressure has to be increased to expel the molten slag. The slag will be expelled from the front until you have pierced through the complete thickness. Slag can therefore be thrown several feet towards the operator.

When starting, if a free edge is not available to commence the boring then the technique is to pierce a hole through completely in the middle. When boring the lance is kept aimed slightly downward and the slag kept in motion by forwards and backwards motion. Sand is placed beneath the slag to protect the floor.

It is simple one man operation and extremely mobile. Under water cutting is possible. Equipment cost is low. The operation speed is high and makes little or no noise while cutting. The cost is reduced / low compared to Oxy-Acetylene cutting.

Adjust the Oxygen between 9 to 12 bar

No, the greater the hardness of concrete or steel, the better the cutting action of the Burning Lance.

Generally speaking, leaving the linear area of about 4 inches of the cut, the concrete structure does not get affected. However, it is suggested that the water is sprayed on the concrete after cutting so that the adjacent areas of structures is safe and cooled after the operation.

Kandi Engineering was incorporated in 1982, and started initial trading activities at Manor (Maharashtra), an Industrial Area just 85 kms from Mumbai, INDIA. Cost saving and good quality being the motto of the management, the production started in 1995 for manufacture of industrial products related to Steel & Metallurgical Industry.

Read More